SEE OUR DETAILS

Measuring 3D Scan Service

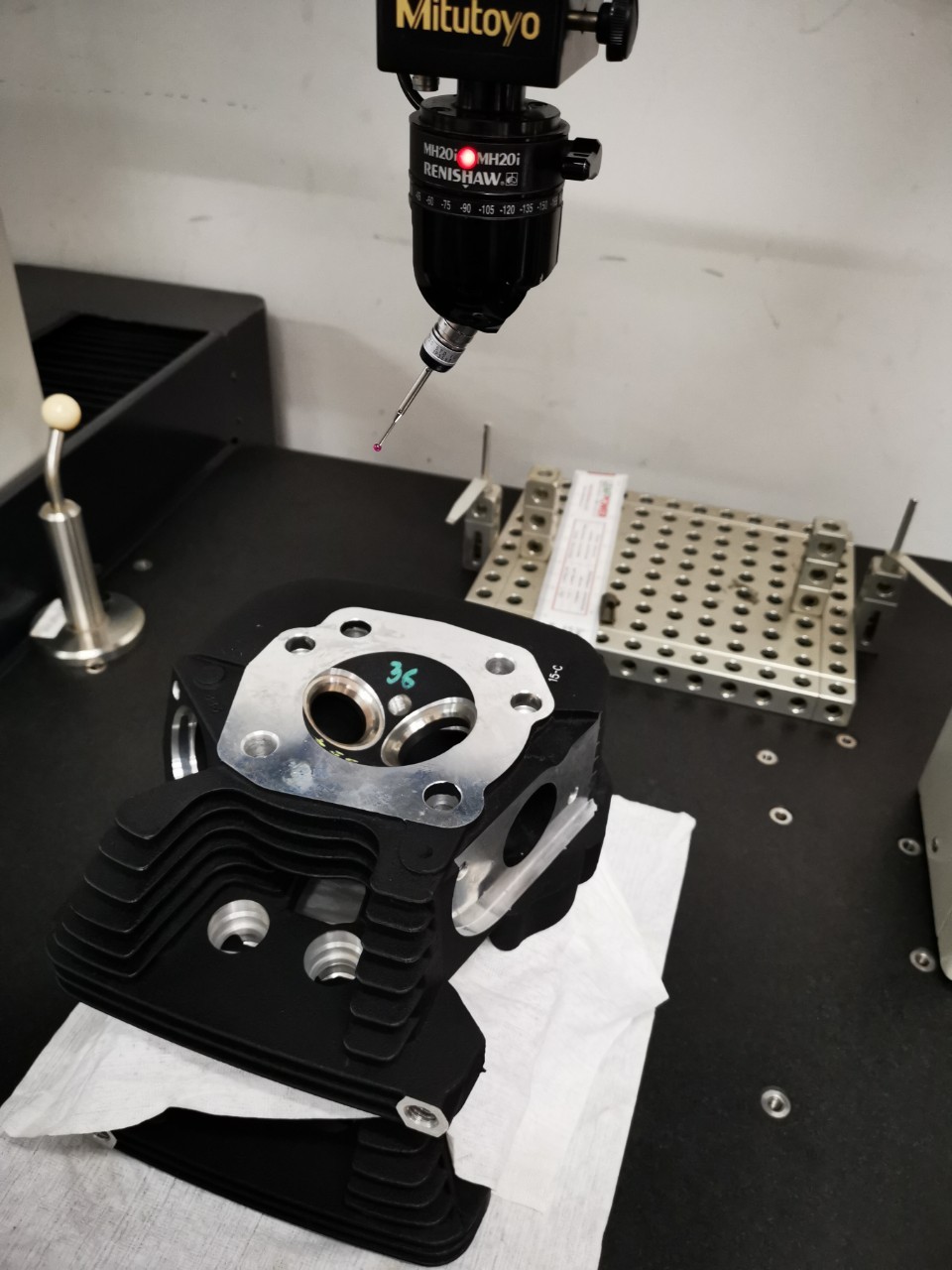

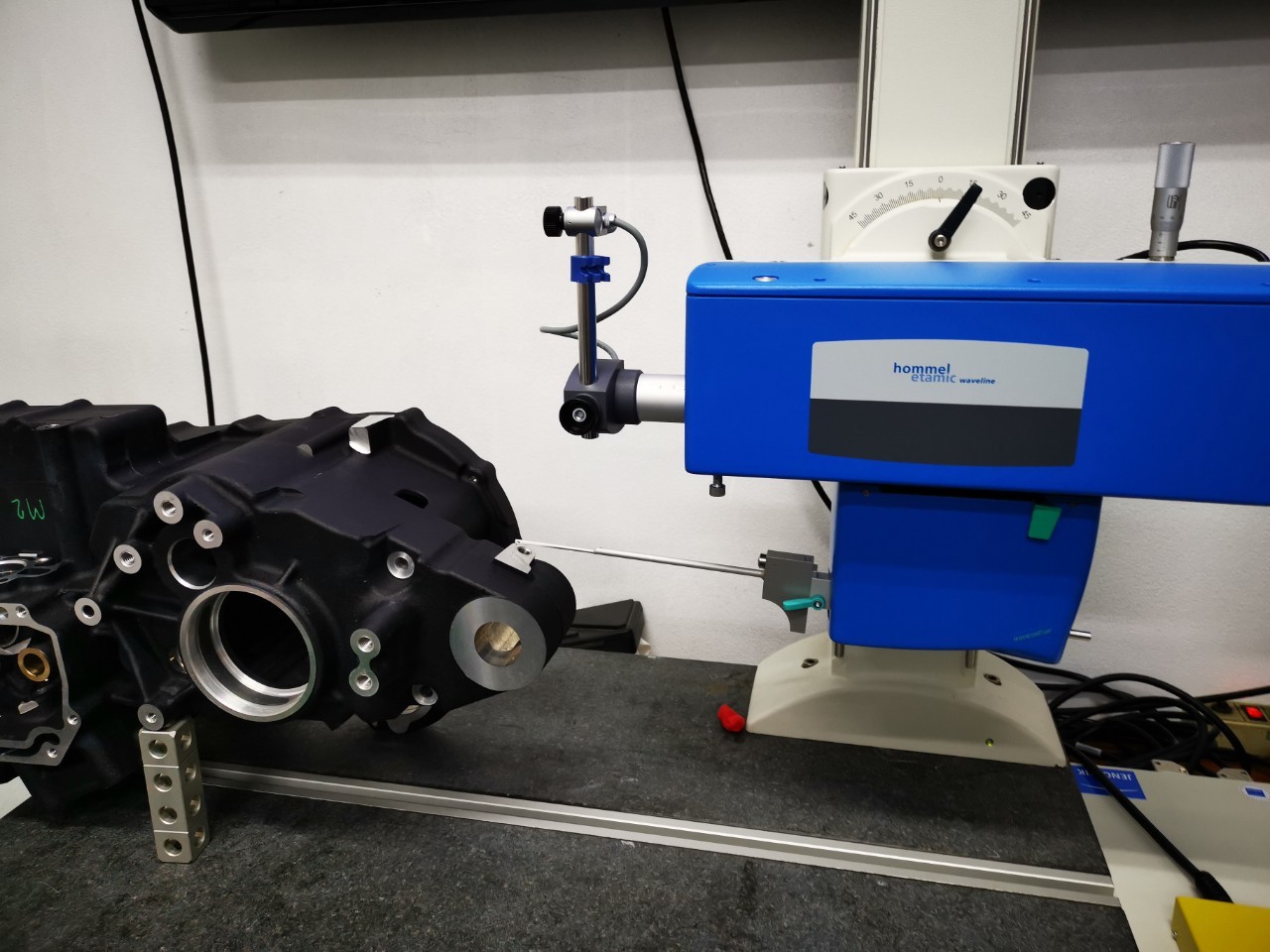

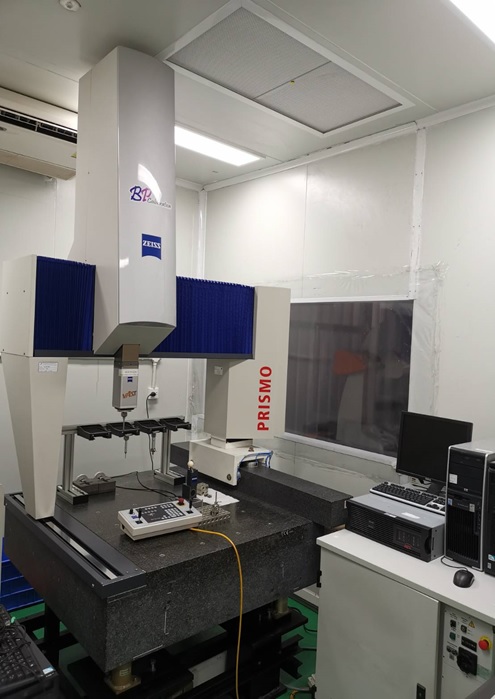

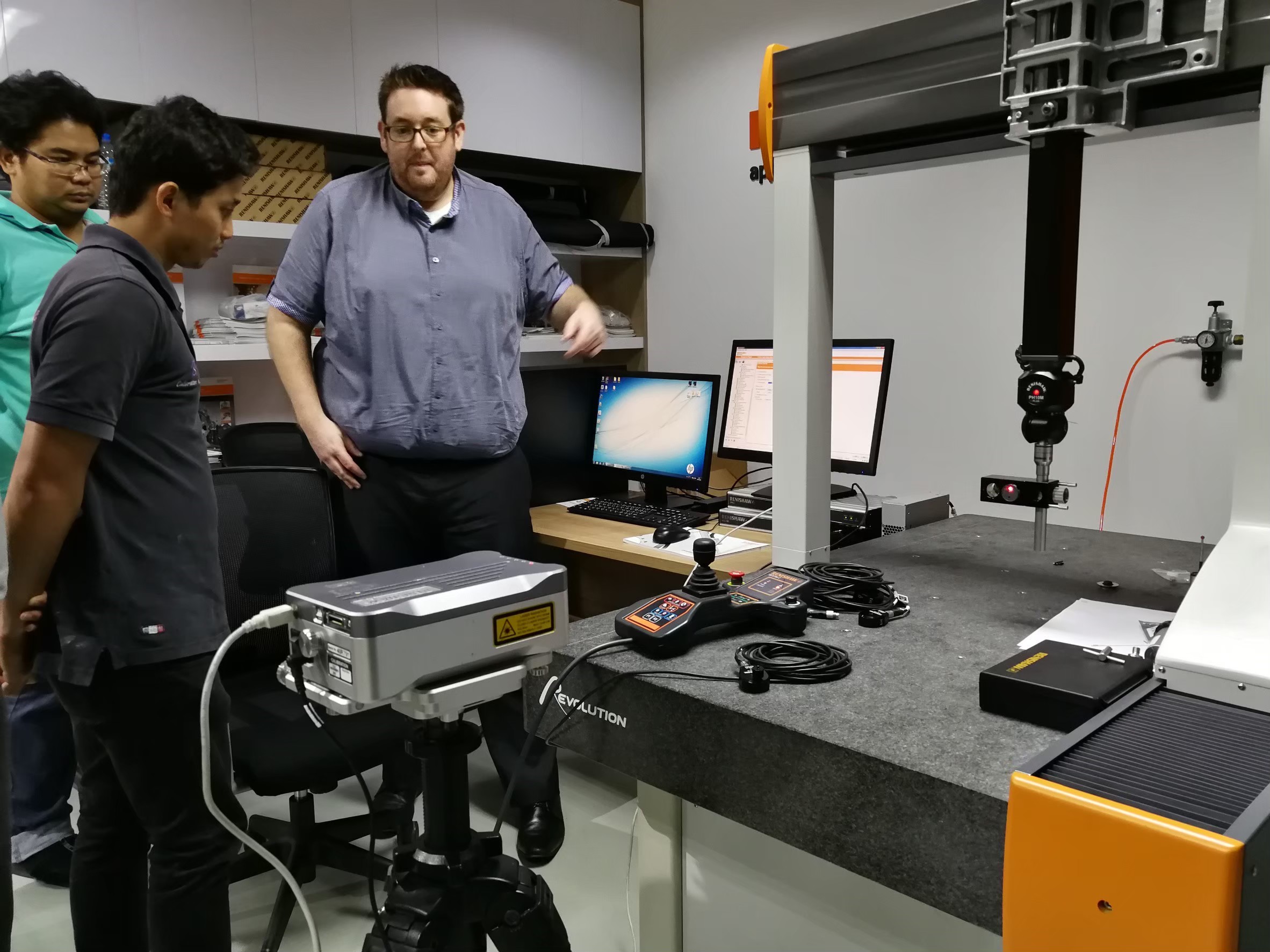

CMM Dimension inspection service

If you want to make sure your piece is as accurate as possible. You can get help from our team of experts. To check the position of the workpiece accurately and precisely with the technology we have, such as the CMM and Contour W800, etc.Which in many large companies Make the machine used to measure the work that is inadequate for use, the BP Calibration Company Limited would like to be another option for you to use the workpiece for service with our company. We can assure you with quality results.

CMM resolution up to 0.0001 mm. Used to measure a variety of tasks supports large work size up to 7 meters and resolution up to 3 micron using modern CAD 3D software.

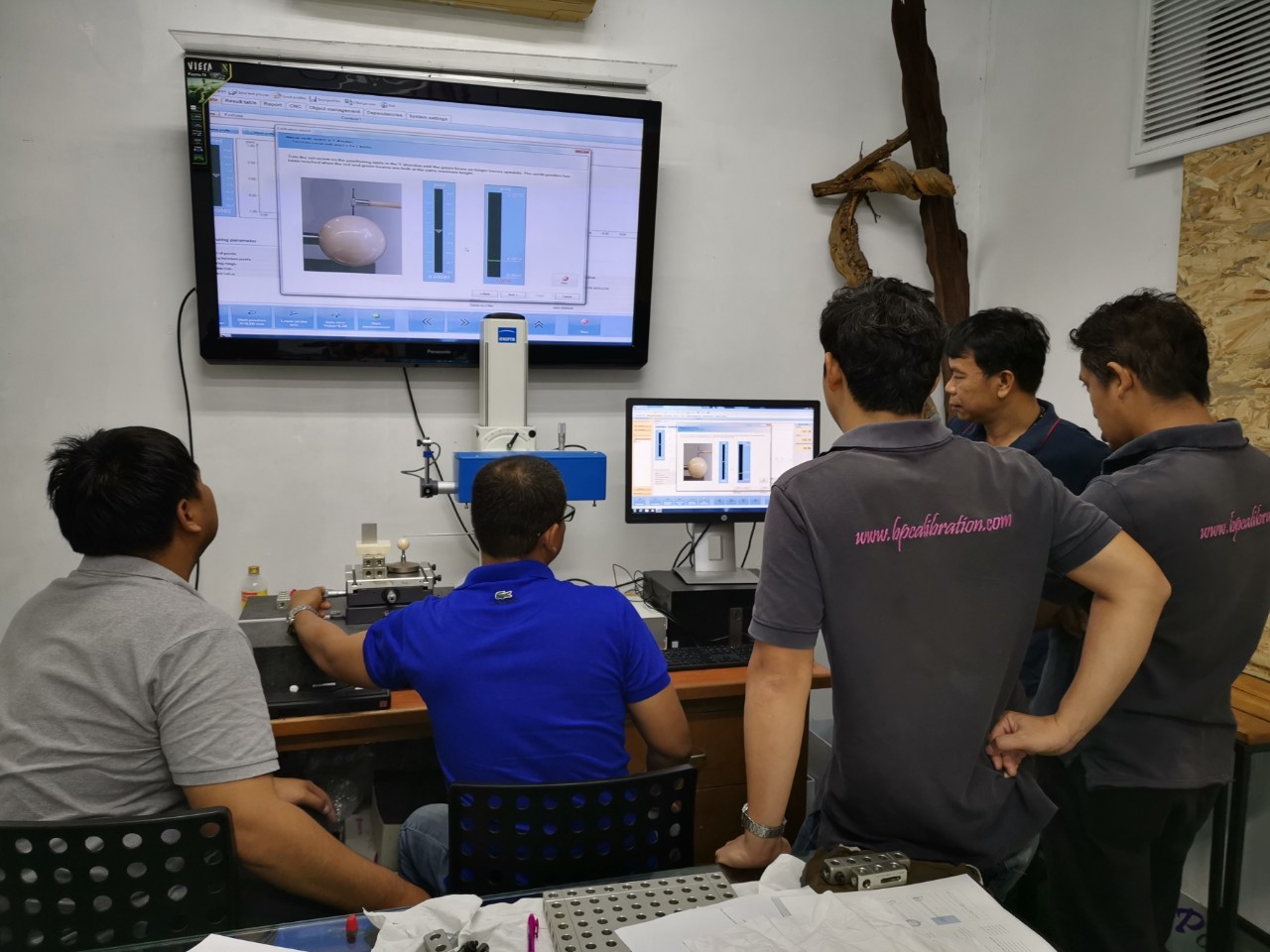

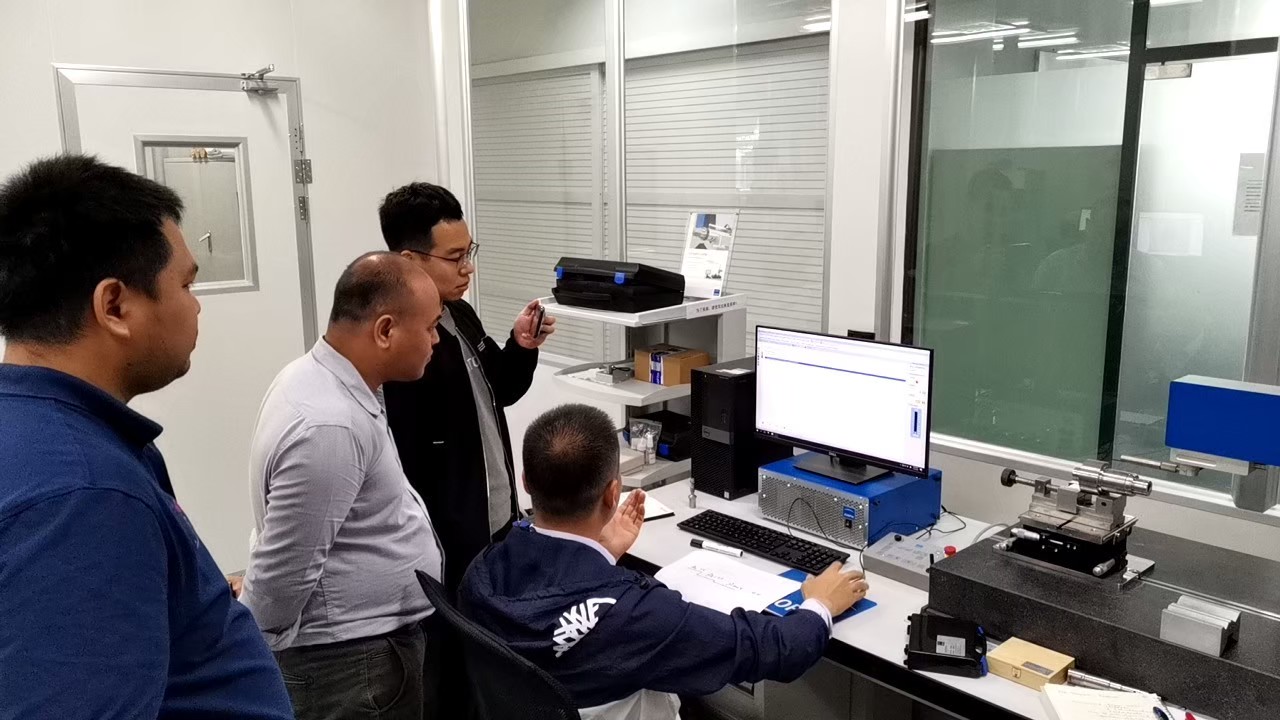

SOFTWARE TRAINING

Software Instructors can help you set up custom training for specific software programs

OUR SERVICE

On-Site training and training courses

The company has a training service to use. In order to be able to operate the machine efficiently without the customer having to travel to another train to waste time traveling Because we have training services in the customer's area.

CMM Training Course

- Training service for the use of Coordinate Measuring Machine (CMM) All brands be it Carl Zeiss, Mitutoyo, Brown & Sharpe, Accretech, Leader, LK etc.The course lasts for 3 days, where CMM users will be able to use the functions of the machine correctly. Send results to the workpiece size measurement that will be accurate. Reliable as wellTraining course

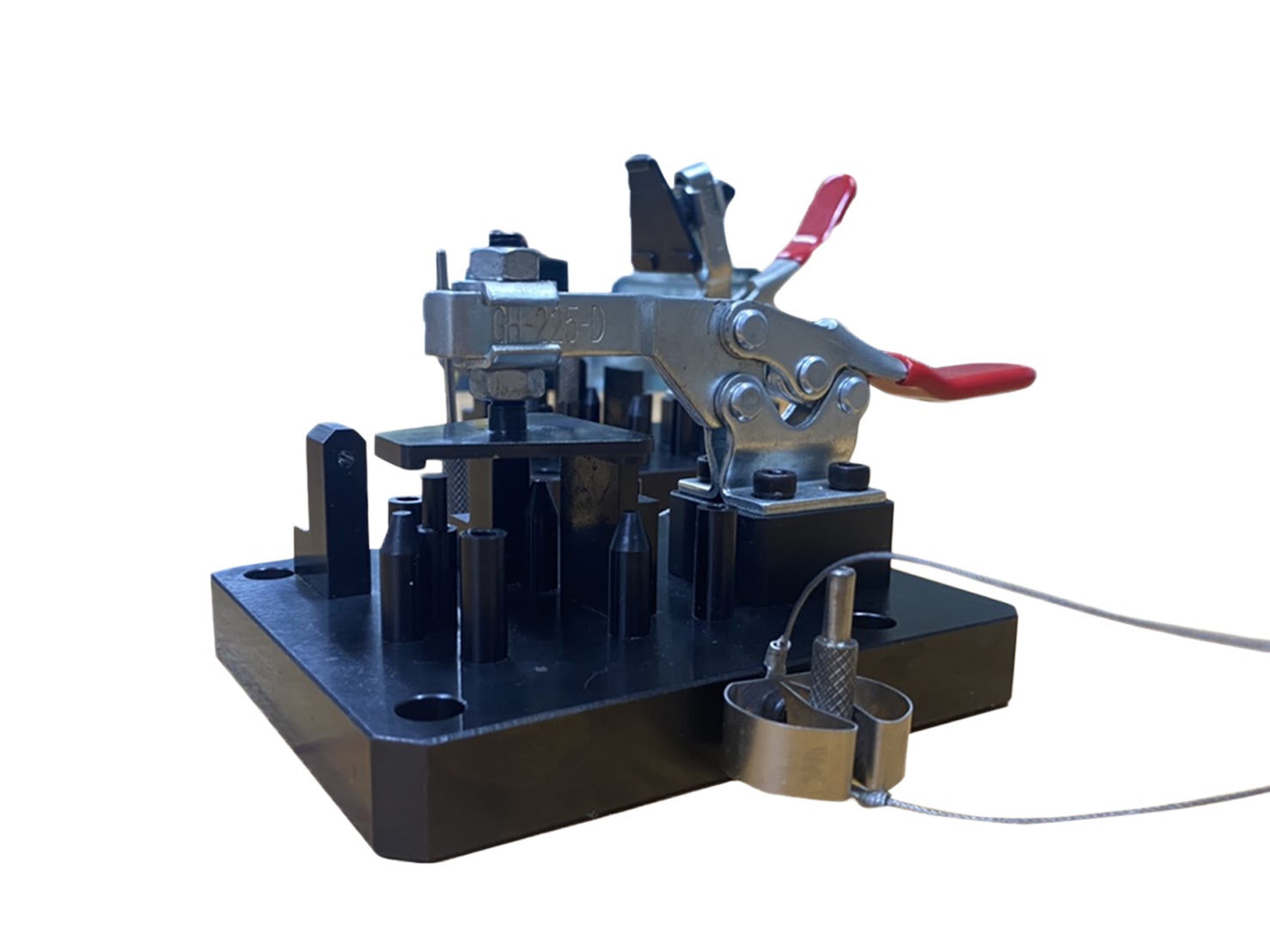

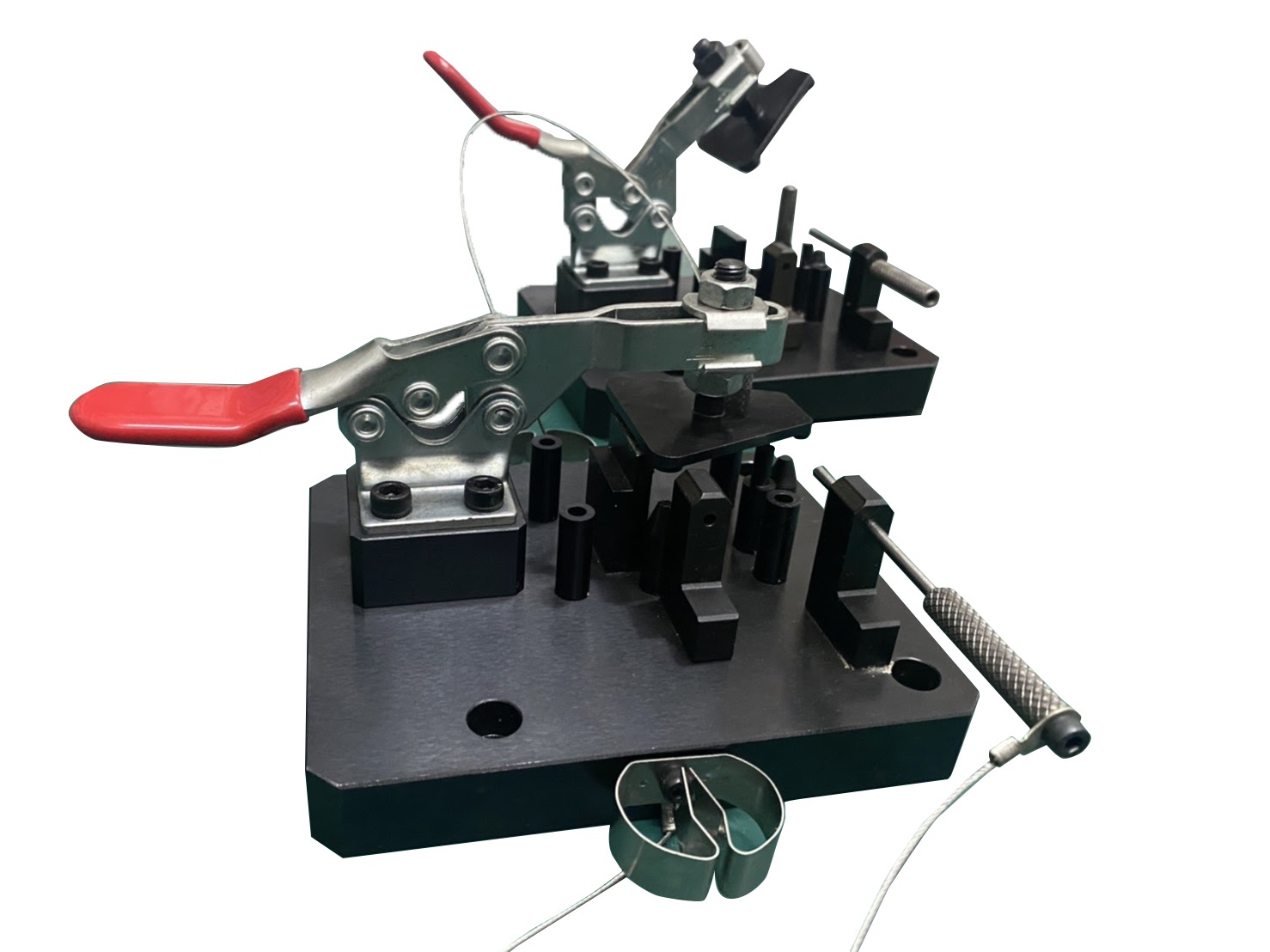

- Service training for the use of machine, roundness meter, surface resolution meter, hardness tester, projector profile (Contour Measuring Machine, Hardness, Roundness, Roughness) for all brands,the course lasts for 2 days. Professionals are brought by you, certified CMM instructors to teach you how to use CMM products at your workplace on your schedule. It's a great way to instantly interact and respond to team questions and discuss employee measurement needs.JIG FIXTURE DESIGN

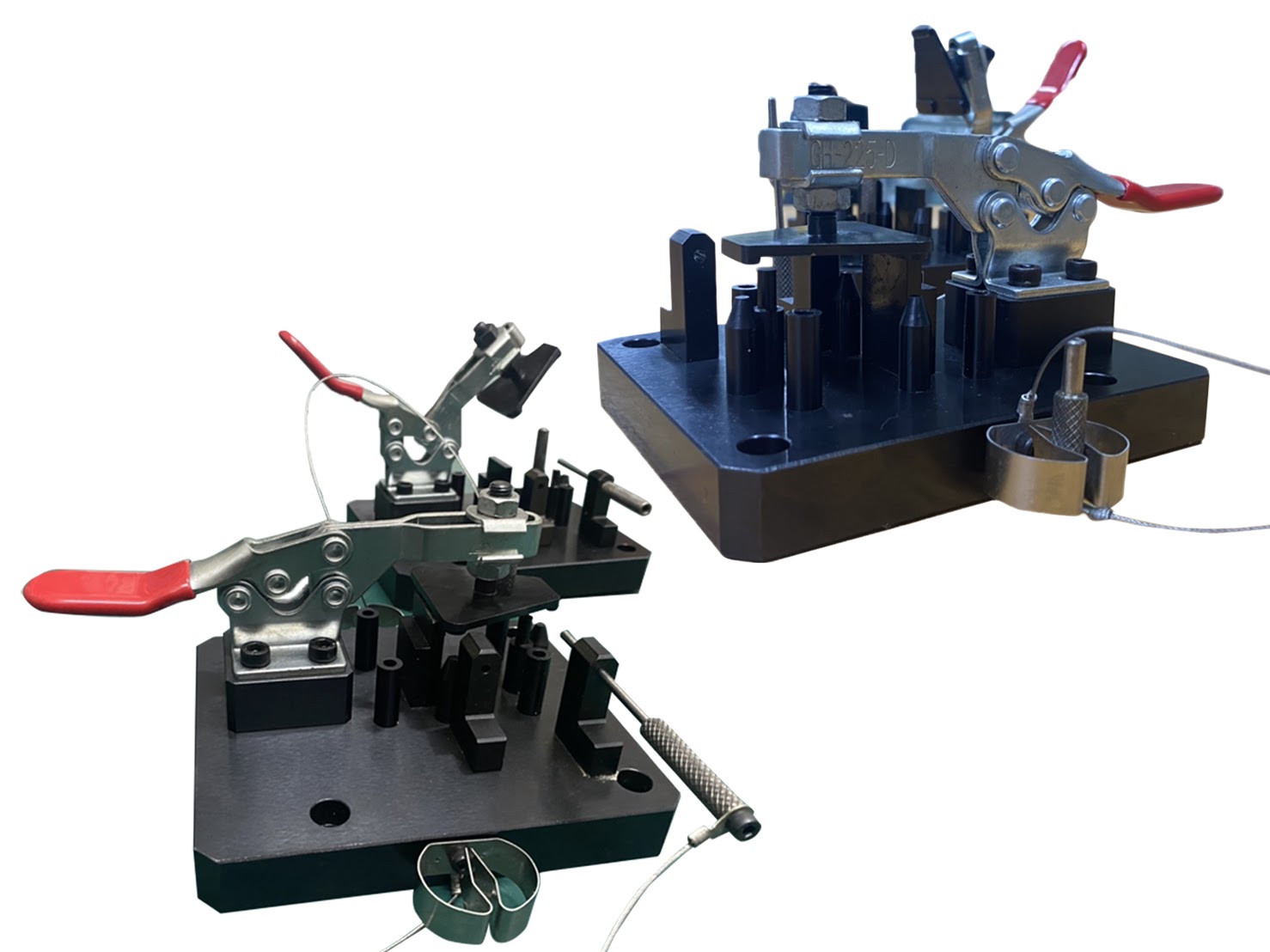

Service of making a set of clamping parts.

Workpiece holding device. That help increase the efficiency of work to be convenient, fast and correct according to the It also improves work efficiency. Help reduce production costs Extend the machine life Reduce working time Increase productivity, such as Welding Jig / Assy Jig / Water leak Jig / Air leak jig / Jig Check and so on.

Automation Design

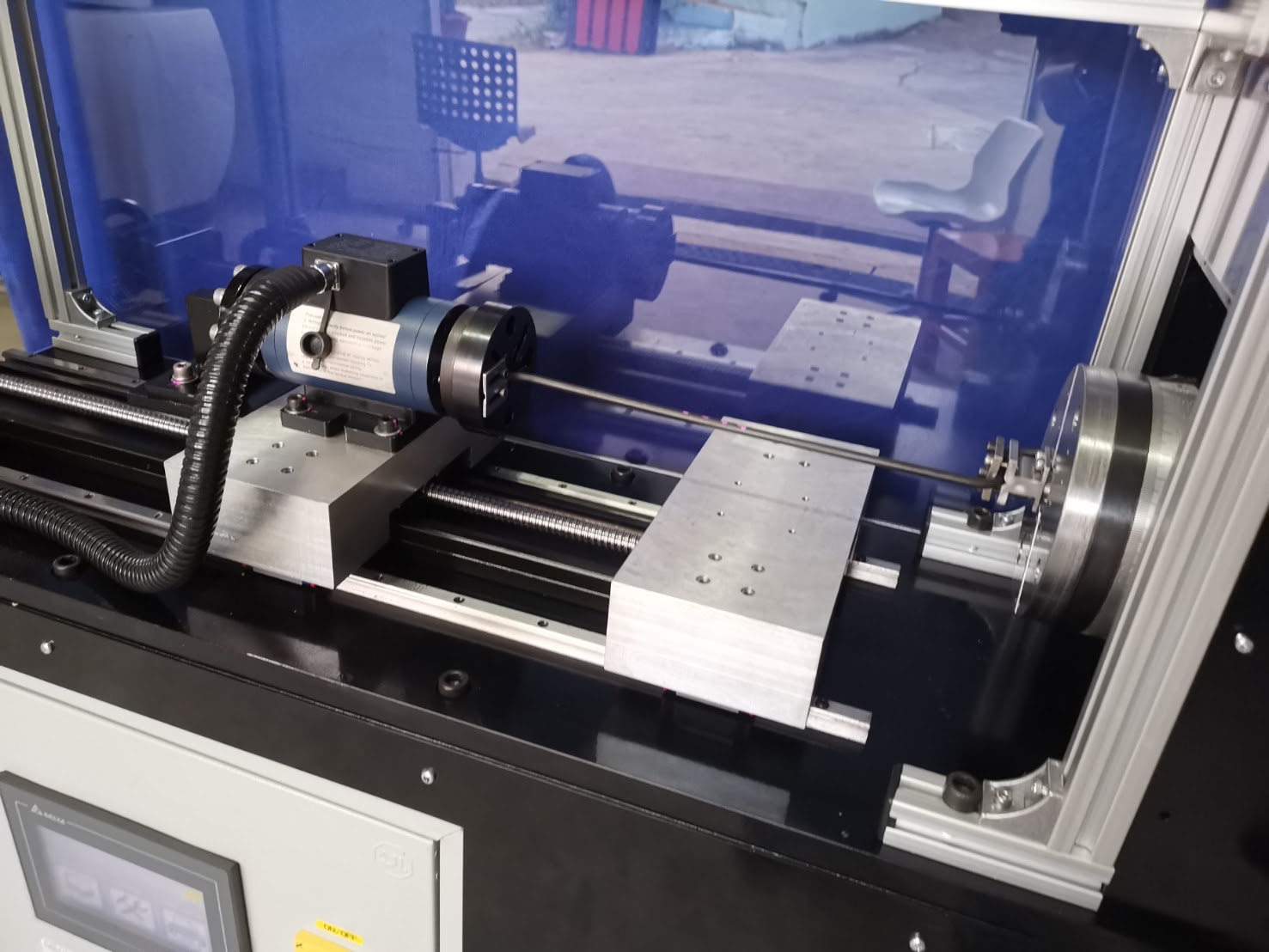

Torsion test machine

WORKING PROCESS

- Machine can work automatically and manually

- Angle value degree

- Machine calculate graph prepare and counting time in HMI

- Machine can select type of 7 style of spring can select program in PLC

- Machine can operate command print in inkjet driver

- Machine can driving smoothly by linear rail

EN

EN  TH

TH